PRODUCTS

We aim to be a sustainable global company that pioneers the future of motorization.

We aim to be a sustainable global company that pioneers the future of motorization.

STRENGTHS OF GMB

01

STRENGTHS

02

STRENGTHS

03

STRENGTHS

04

STRENGTHS

GMB's

There are various costs involved in operating a business. Among them, costs related to products include development costs, procurement costs, quality management costs, customer support costs, and more. GMB primarily contributes to reducing your company's procurement and quality management costs out of the many costs you carry.

Narrowing the product range allows for increasing the lot size, which can deliver a reduction in production costs. Therefore, many component manufacturers narrow their product ranges to lower production costs. However, in that case, the buyer needs to deal with various suppliers, such as Company A for parts of this car model, and Company B for other parts. As the number of suppliers increases, the costs associated with procurement, including administrative tasks for ordering, fees for payments, as well as communication costs and inventory management costs, also increase. Conversely, with GMB, which covers parts for many car models, it is possible to procure a diverse range of components from a single company. GMB goes beyond being a simple parts manufacturer to also serve as a partner that can solve your ongoing business challenges.

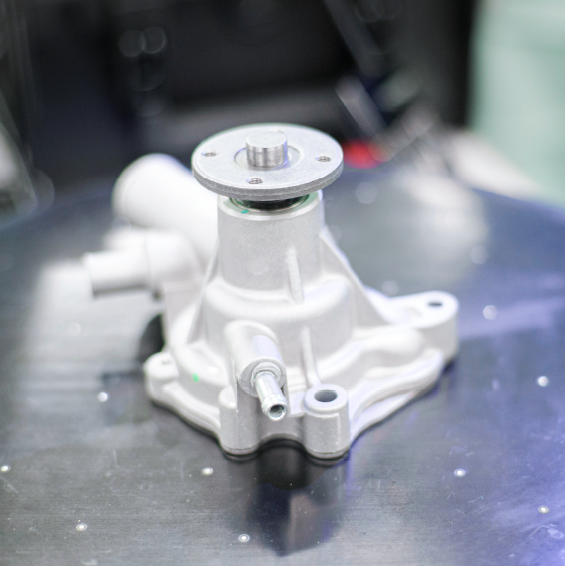

GMB delivers OEM services to major domestic and international automotive manufacturers, ranging from mass-produced passenger cars to luxury vehicles.

For many years, GMB has been engaged in all stages of the production line, including product design, material selection, procurement, manufacturing, processing, and polishing, at its main factory in Nara and the Yao factory in Yao, Osaka. Additionally, GMB has a solid track record of conducting inspections consistently after production.

Currently, GMB has multiple production and sales bases overseas, including factories and more, in addition to its domestic operations. The knowledge and vast amount of data cultivated through integrated production at domestic factories are effectively utilized across all factories and locations both at home and abroad.

At GMB, we strive to minimize unnecessary costs and reflect cost reductions in our product prices. However, in terms of quality management, we aim to maintain a high level of quality on the production line, investing in cost-effective measures to ensure minimal defects and prevent customer dissatisfaction.

GMB's

At GMB, we rigorously manage quality at our mother factories in Japan, as we strive to produce products that are completely defect-free. At our overseas factories as well, we regularly dispatch engineers and quality control specialists to provide technical guidance, drive quality improvement, and conduct quality audits. Through these measures, we maintain the same level of quality as our Japanese factories at home.

We employ the latest measuring instruments and analysis equipment to conduct high-precision inspection and analysis, thereby ensuring the precision of our products.

Through these efforts, we maintain a stable and consistent quality with minimal variations between products. While GMB does manufacture non-genuine parts for general consumers, the manufacturing processes and quality control standards employed are equivalent to those for our OEMs. The quality level remains consistent even for aftermarket parts, and the fact that GMB's products are adopted by numerous automotive manufacturers attests to the trust and proven track record of GMB.